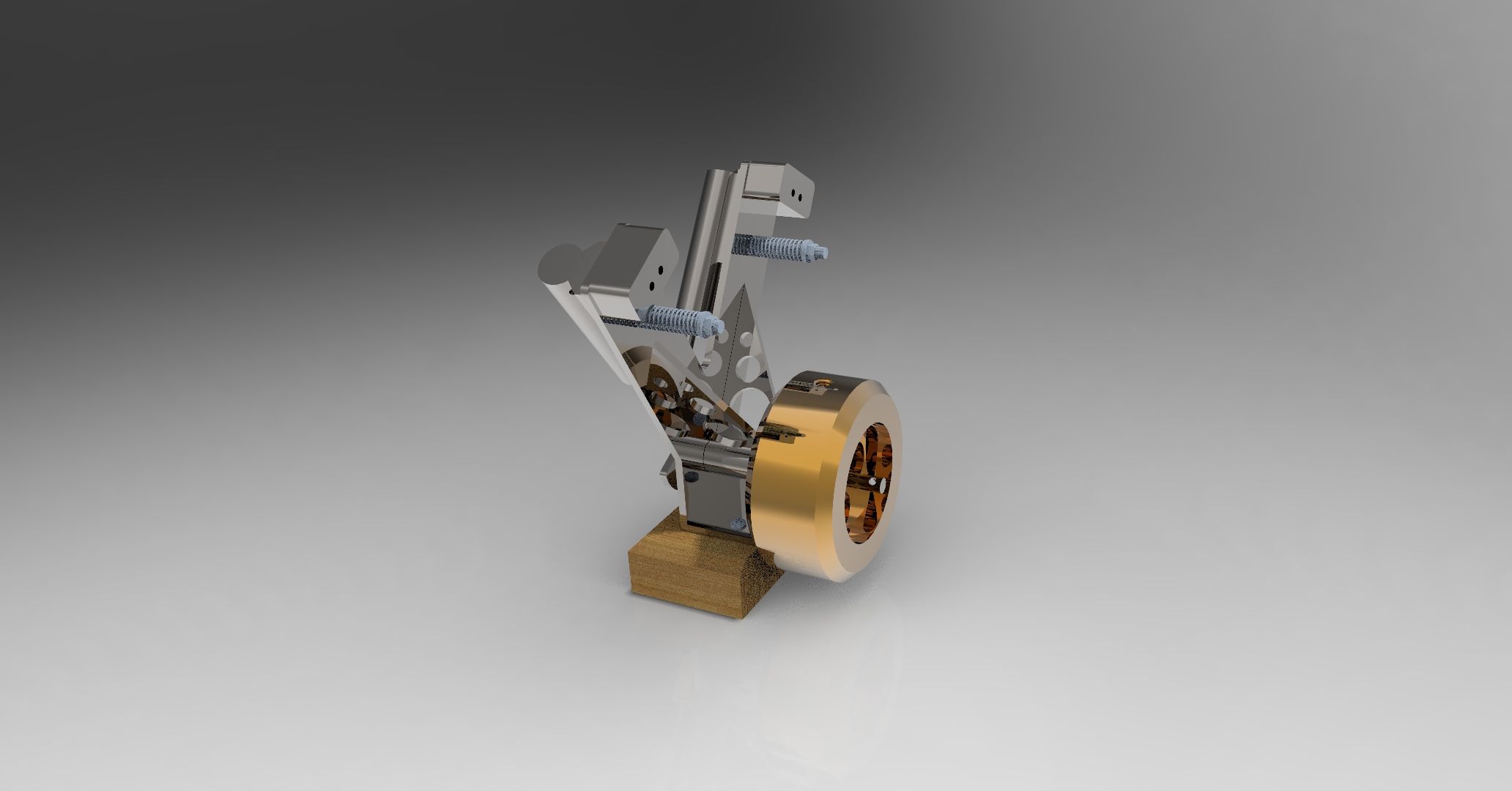

Twin Oscillating Steam Engine

A twin oscillating steam engine is a type of reciprocating steam engine that converts steam pressure into mechanical energy by using two oscillating cylinders. It was popular in the nineteenth century and is known for its quiet operation and small size. It is now commonly used in hobbyist and educational projects to demonstrate the principles of steam power and mechanical engineering.

60

0

Introduction

Allow me to introduce the twin oscillating steam engine. It is known to be a very simple engine that is easy to maintain and very cost efficient mainly due to its design and limited capabilities. However, these limited capabilities are still more than enough for uses in full-size working engines, mainly on ships and small stationary engines in the past. As engines became more advanced the twin oscillating steam engine became more irrelevant but still holds an important role in engine development over the years as it allowed the bright minds of today to use it as a setting point for further improvement in the world of engines.

objectives

The Objective of the twin oscillating steam engine is to generate power for the engine to be used with ease. A simple module for a simple task while maintaining a low cost of manufacturing and operating.

Method

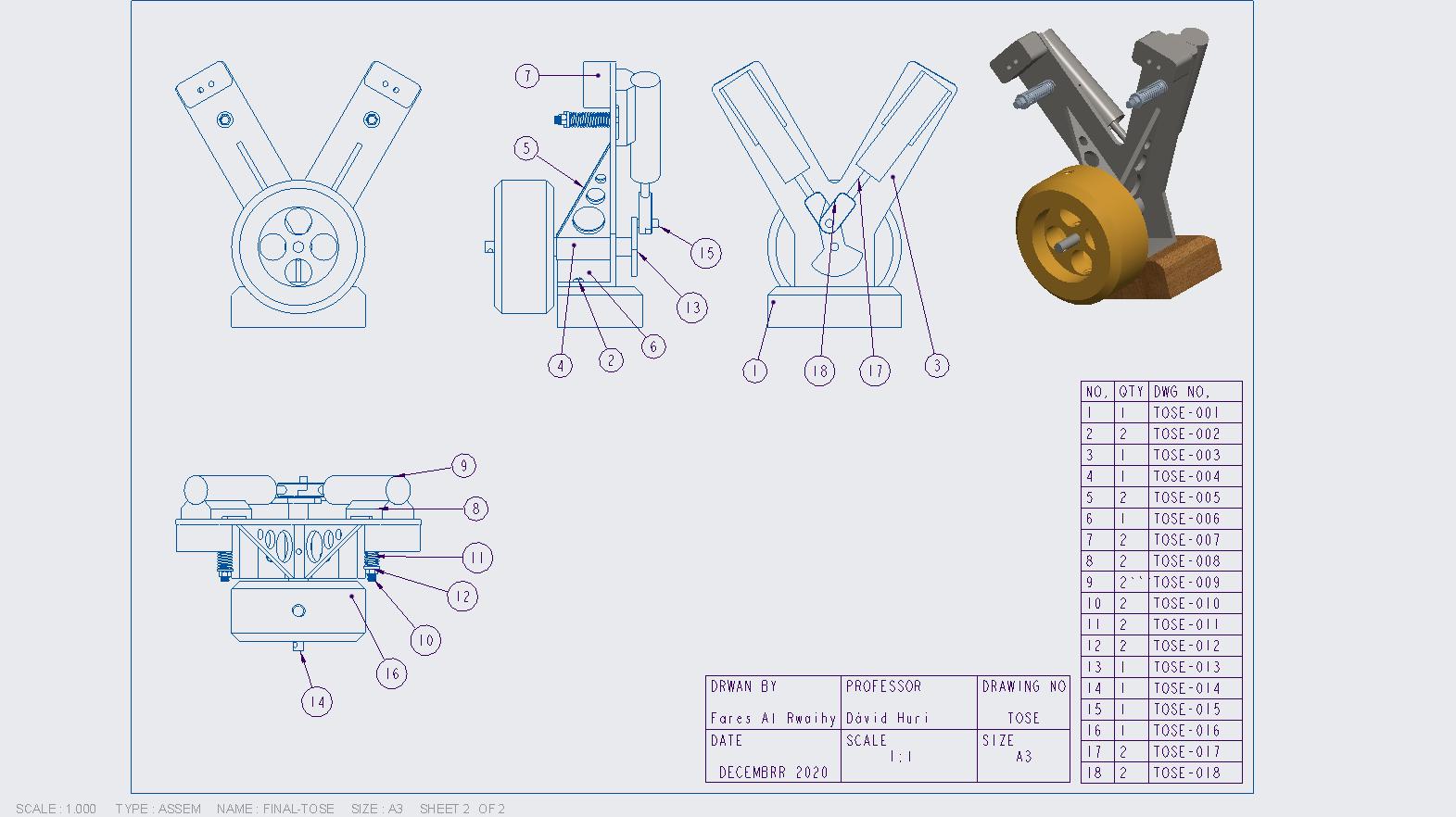

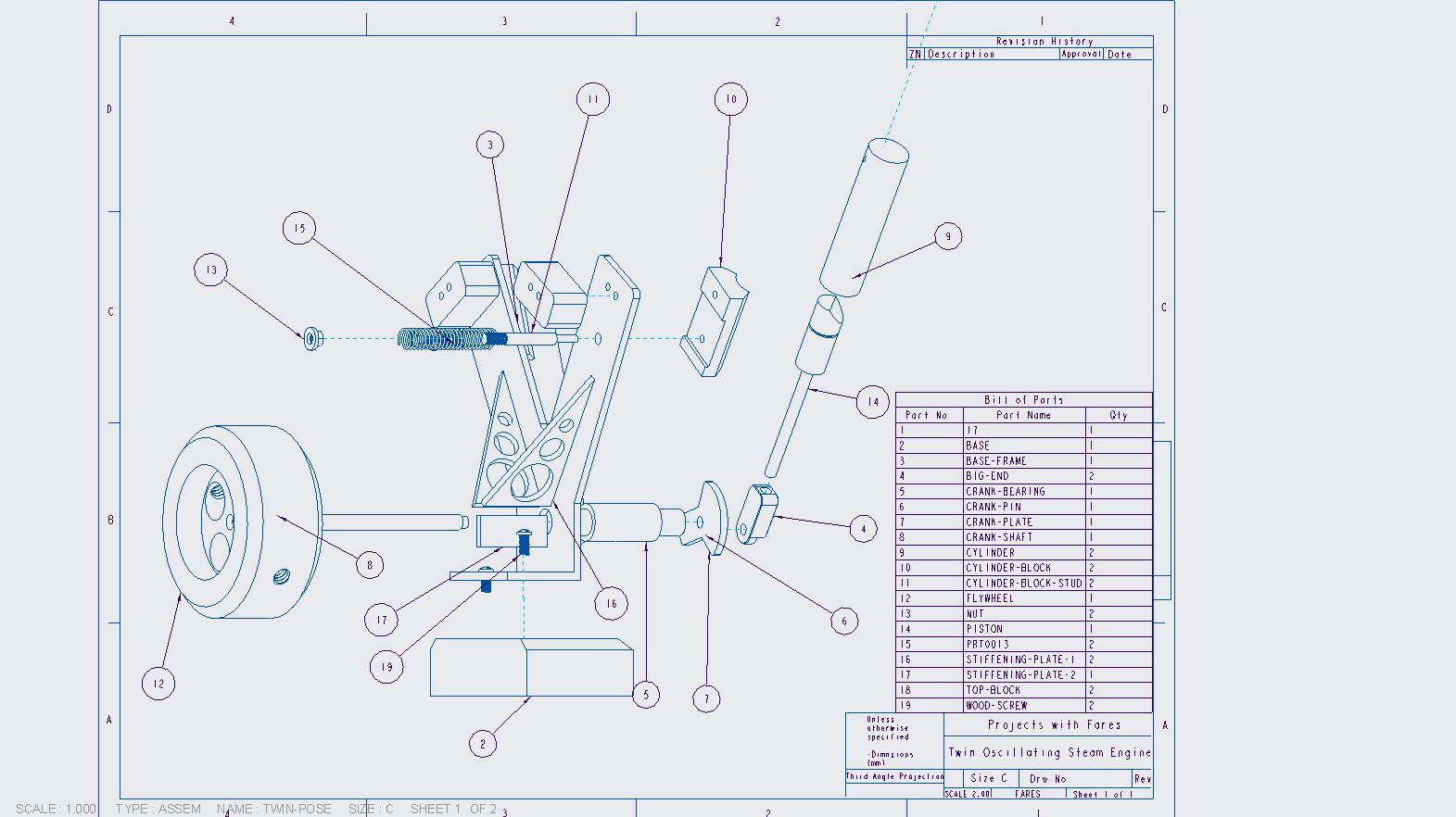

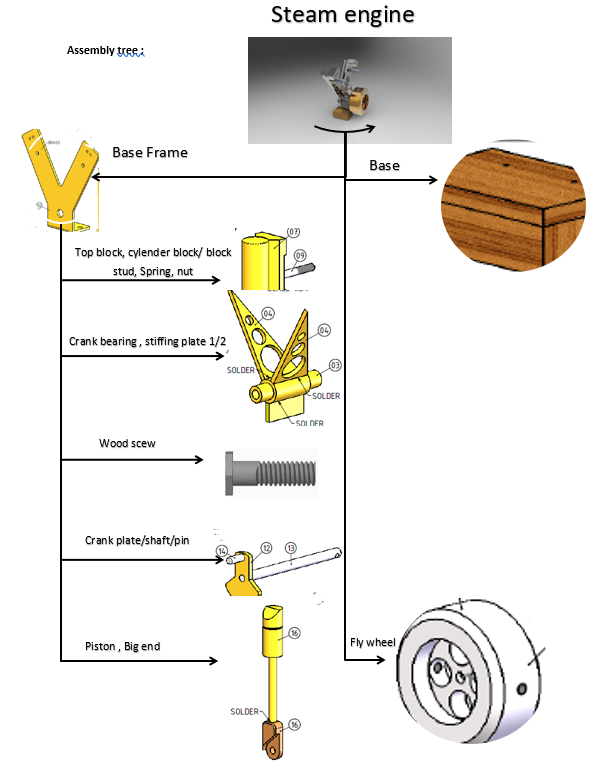

Assembly of the twin oscillating steam engine is not too complex just like everything else about it. The way it works is simple, The steam needs to be fed into the end of the cylinder at just the right time in the cycle to push the piston in the correct direction. In the other direction, the steam needs to be allowed to escape from the cylinder. As the crankshaft rotates, the piston rod moves up and down (or side to side in the case of a vertical cylinder) as well as in and out. Because the piston rod is rigid and the piston itself is long relative to its diameter, this causes the cylinder to rock, or "oscillate" on its special mounting. In the design usually found in a toy or model engine, a hole in the side of the cylinder (one at each end for a double-acting cylinder) and a pair of holes in the port block are arranged so that this rocking motion lines up the holes at the correct times, allowing steam to enter the cylinder in one direction and to escape into the atmosphere or condenser in the other direction.